This article first appeared in The Atlantic on January 24, 2022. Re-printed with permission.

On September 13, 2021, I took my first plane trip in 18 months: Kansas City to Boise with a layover in Denver. The trip itself was largely uneventful, with one exception. After I boarded my connecting flight in Denver, a pilot announced that we would be briefly delayed because Air Force One was also en route to Boise. President Biden was responding to yet another record-setting wildfire season, during which 5.3 million acres of the U.S., an area the size of New Jersey, had already burned. “We can’t ignore the reality that these wildfires are being supercharged by climate change,” he would say later that day. “It isn’t about red or blue states. It’s about fires. Just fires.”

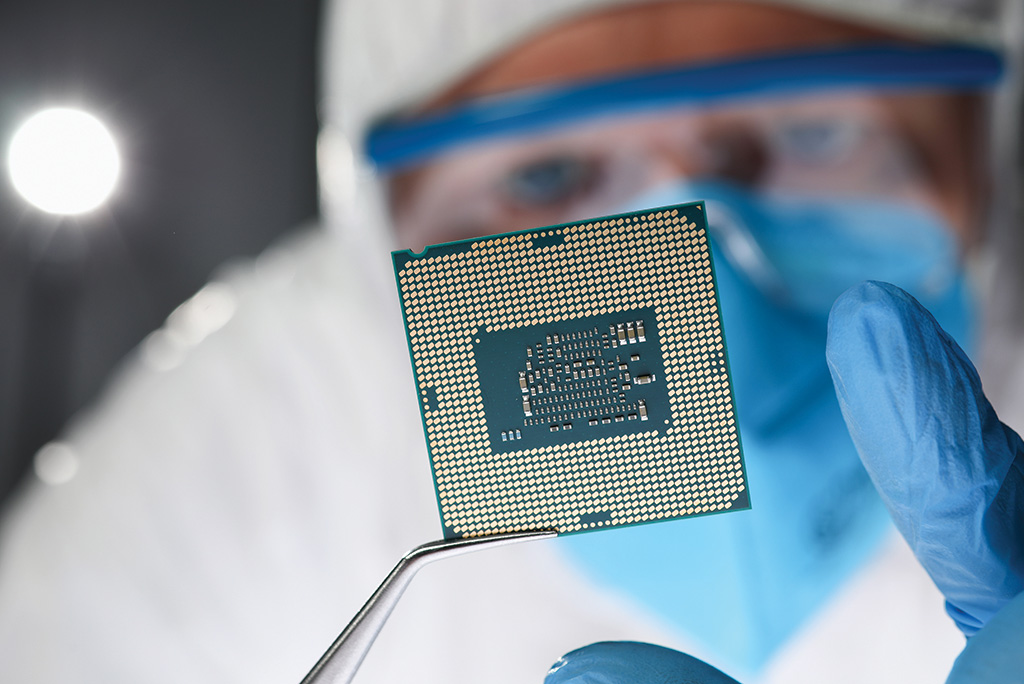

The wildfires had both everything and nothing to do with my trip to Boise and, from there, to the Salmon-Challis National Forest, a five-hour drive northeast of the city. For me, the area’s most immediate draw was cobalt, a hard, silvery-gray metal used to make heat-resistant alloys for jet engines and, more recently, most of the lithium-ion batteries for electric vehicles. The Salmon-Challis sits atop what is known as the Idaho Cobalt Belt, a 34-mile-long geological formation of sedimentary rock that contains some of the largest cobalt deposits in the country. As the global market for lithium-ion batteries has grown—and the price of cobalt along with it—so has commercial interest in the belt. At least six mining companies have applied for permits from the U.S. Forest Service to operate in the region. Most of these companies are in the early stages of exploration; one has started to build a mine. In Idaho, as in much of the world, the clean-energy revolution is reshaping the geography of resource extraction.

The rugged Salmon River Canyon. Cobalt, a highly sought-after metal used to make lithium ion batteries, lies beneath the surrounding mountains.

And so it was that, on a pleasantly cool late-summer morning, I found myself in the back seat of a Ford Expedition alongside the mining engineer Matthew Lengerich. As the executive general manager of mining for Jervois Global, the Australian company that owns the new mine, Lengerich was my guide for the day. Lengerich has been in the mining industry for the past 23 years, and before joining Jervois in August, he worked for the Anglo-Australian mining giant Rio Tinto. He told me that he switched companies, at least in part, because of his interest in electric vehicles. “The EV story is one that I personally believe in,” he said. ”I think it’s here to stay. I’m happy to share that I saw the initial trailer for the F-150 Lightning and went, ‘That’s really cool.’”

For most of our hour and a half drive from Jervois’s office in the town of Salmon to the Jervois mine, we bumped along a dirt road that ran adjacent to several creeks and down a series of vertigo-inducing switchbacks. Lengerich said he had recently seen black-bear cubs run across the road; I saw a grouse and two mule deer. “This is our commute to work,” Lengerich said, with a hint of genuine awe. “We’re not sitting in traffic on I-15. You get to drive this.” He pointed out the window to rugged mountains covered in ponderosa pines and Douglas firs. Yet cobalt mining has already changed this landscape, and is poised to do so again.

Cobalt is used in semiconductors and more recently lithium ion batteries needed for cell phones and electric vehicles. Congress recently approved the $280 billion CHIPS and Science Act of 2022 that aims to boost the United States’ self-reliance on cobalt and lithium.

The lone access road to the Jervois mine cuts through what was once the only cobalt mine in the U.S., the 10,830-acre Blackbird Mine. Now a toxic waste site, it includes a 12-acre open pit, 4.8 million tons of waste rock, 2 million tons of tailings, and enough tunnels that, if they were strung together, you could run a half marathon in them and still have nearly a mile to spare. As we drove through, we passed the crumbling concrete remains of a tailings mill, then a log-framed portal covered by a plywood door. The water-treatment plant, however, was still operating.

Blackbird closed in the early 1980s after more than 30 years of intermittent operations. By then, the surrounding creeks were lifeless; heavy-metal pollution had killed off most of their fish and aquatic insects. The concentration of copper in one creek was so high that the water turned bright blue. (Copper is often found in the same areas as cobalt.) In 1993, the Environmental Protection Agency proposed adding Blackbird to its National Priorities List, a designation reserved for the worst-contaminated sites in the country. Ultimately, the EPA negotiated a settlement with the companies that owned the mine. But the agency did label the mine as a Superfund site, initiating a cleanup that has so far cost the companies more than $100 million.

When I asked people in the cobalt industry about Blackbird, many pointed out that mining practices and regulatory oversight have improved in recent decades. But accidents can still happen. “Man is imperfect,” said Daniel Stone, a policy analyst for the Shoshone-Bannock Tribes, whose historic homeland covers the southern half of Idaho and large portions of bordering states. “Small flaws could lead to big problems down the road.” For Stone, those problems are deeply personal: Mining not only polluted the Shoshone-Bannock homeland but led to the forcible removal of Shoshone people from the area in the late 19th century. “It’s what some people would call historical trauma,” Stone said. “But I have a problem calling it historical trauma, because it never stopped.”

Stone told me that the tribes don’t necessarily oppose new mines on their ancestral land. They do, however, expect companies to prevent pollution and restore the landscape before they leave. To that end, federal regulations required Jervois to post a $30.8 million reclamation bond to fund cleanup activities after the mine closes. “The hope is always that this mine does not become a detriment to environmental health,” Stone said. “But I’m definitely not so naive as to think that there’s not at least the potential for problems to develop.”

When we arrived at the Jervois mine, the sky was clear and blue, though smoke from distant wildfires would turn it gray by the end of the afternoon. I followed Lengerich out of the car and to a pile of rocks that served as a makeshift overlook. Below stood a half-dozen steel-and-concrete buildings in various stages of completion. In the distance were a water-treatment plant; two water-management ponds; a tailings-storage facility; and the beginnings of a “man camp,” a collection of prefab houses where miners will live during their shifts. “Today’s a big day for us,” Lengerich said, explaining that contractors were scheduled to pour the last of the foundation for the building directly in front of us, where two mills would eventually grind cobalt ore into sand-size grains for processing.

A tributary to the Salmon River, Panther Creek was severely damaged by copper, arsenic and cobalt released into area streams from the former Blackbird Mine. From the 1960s through the 1980s, no fish and few aquatic insects could be found in long stretches of Panther Creek. Efforts to restore the stream’s water quality began in 1995. Today, Panther Creek is home to diverse species including Chinook salmon, steelhead, rainbow trout and bull trout.

The entrance to the mine was under construction on the northwest side of nearby Gant Mountain, at an elevation of 7,080 feet. There, a massive machine resembling a one-armed praying mantis was drilling 12-foot-long steel bolts into the treeless mountainside. Gusts of wind stirred up clouds of dust as the machine, called a jumbo, lumbered from one position to the next on a narrow dirt road. The mine itself will consist of three vertical, corkscrew-shaped tunnels descending more than 1,300 feet underneath the mountain. As we watched the jumbo, Lengerich stressed that the environmental impact of it all would be minimal. Jervois has pledged to backfill and seal off the underground tunnels, reclaim as many roads as possible, and revegetate the site with native plants. “In 30 years, you’ll have no idea there was a mine here,” Lengerich said. “Everything will be put back the way it was.” He paused for a moment, then corrected himself. “Thirty years might be a bit soon,” he said. “I’d say 40 to 50 years.”

Jervois estimates that its mine in the Idaho Cobalt Belt will produce 1,915 metric tons of cobalt annually, enough for about 160,000 electric-vehicle batteries. That’s a drop in the bucket compared with the output of mines in the Democratic Republic of the Congo, which, as home to more than half of the world’s known cobalt reserves, produced 95,000 metric tons of cobalt in 2020, about 70 percent of the global supply. With little oversight and few safety measures, the mining industry in the Congo is notoriously dangerous. Men work in hand-dug tunnels that can extend hundreds of feet underground, while children as young as 7 sift through tailings on the surface. Wages are poor. Cave-ins are common. And the long-term health effects of the work, including chronic lung disease caused by inhaling dust, can be deadly. Some can even be multigenerational: A recent study in the Congo that was published in The Lancet found that men who worked in mines were more likely to father children with birth defects than those who did not.

Last year’s large Mud Lick Fire came very close to the former Blackbird mine (site of the new Jervois mine) and, at press time, this year’s Woodcock Fire was still burning in the region.

The majority of cobalt mined in the Congo is exported to China—84 percent in 2019. In a report on strategically important supply chains issued in June, the White House rated the nation’s cobalt supply more vulnerable than any other metal. Though the report raised supply concerns about other metals that are needed to make lithium-ion batteries, namely lithium and nickel, it described the cobalt market as “one of the most comprehensive ways China has gained a competitive advantage in the critical materials landscape for batteries.”

The nation’s—and the world’s—reliance on China and the Congo for cobalt has attracted companies to the Idaho Cobalt Belt. That was the case for Trent Mell, the CEO of Electra Battery Materials, a Canadian company that is Jervois’s main competitor there. “America could solve a lot of its reliance issues [with] cobalt in this belt,” Mell told me when I met him one morning in Salmon. “But to do that, we’re going to need to be more open and accepting to mining and mining on federal lands.” When I later asked him what he would like to see change, he said that a shorter federal permitting process would be a good place to start. Jervois’s mine took eight years to get permitted.

In addition to Electra’s mining claims in the Idaho Cobalt Belt, the company also owns a cobalt refinery in Ontario, Canada, the first in North America. Though Mell said that a fully operational Idaho mine is at least five years away, the refinery, which for now plans to import cobalt from two mines in the Congo, is on track to open late this year. The refinery’s location 500 miles north of Detroit positions it to contribute to the electric-vehicle industry in the U.S., which received a major boost in August when Biden set a national goal of electric vehicles representing half of all new-vehicle sales by 2030.

The area is home to many wild animals including bighorn sheep.

No one really knows how much cobalt is in the Idaho Cobalt Belt. Many deposits haven’t been measured, and others may be as yet undiscovered. Geologists are fairly sure that the Jervois and Electra claims encompass more than 40,000 metric tons of the metal, enough to fulfill U.S. demand for five years. But whether the two operations lead to a boom in the belt remains far from certain. “A lot of companies are in a wait-and-see mode,” says Josh Johnson, a geologist at the Idaho Conservation League. If the price of cobalt stays high enough for the Jervois mine to be successful, he said, “I think we’ll see more.”

Johnson’s group, which has fought for decades to protect the state’s forests and streams from mine pollution, is watching the new and proposed cobalt mines closely, evaluating them on a case-by-case basis. “Do we have a moral obligation to mine cobalt here in the U.S.?” asks Idaho Conservation League Executive Director Justin Hayes. He suggests that the answer is yes: He’s well aware of the human-rights abuses documented in the Congo, and of the need to secure a reliable supply of cobalt in order to reduce the threat of climate change. Still, he emphasizes that “sustainable mining,” a term used often by industry insiders, is a misnomer; the best anyone can hope for is “environmentally responsible mining.”

More cobalt mines inevitably mean more environmental risks, especially when you consider that metal mining generates more toxic waste than any other industry in the United States. Even if none of the mining operations being developed in the belt ends up as a Superfund site, they can still cause damage—sometimes even before they start production. In October 2021, for example, the Idaho Department of Environmental Quality fined an Electra subsidiary $95,000 for “unpermitted discharges” into a creek about 20 miles southeast of Blackbird. The discharges came from adits the company uses for exploration.

Lengerich points out that the treatment plant under construction at the Jervois mine could operate for 100 years if necessary, much longer than the expected lifespan of the mine itself. “I like the idea of hoping for the best and planning for the worst,” he says. But how do we plan for the worst when, because of climate change, the worst is both unpredictable and incomprehensible? As the floods, fires, heat waves, and hurricanes of the past year illustrated, many once-reliable systems are newly vulnerable.

On our drive back to Salmon, Lengerich and I passed by a fire line that Forest Service crews had cut to protect the town from a recent wildfire. Lengerich said the fire had come within half a mile of the Jervois mine site, limiting access for three weeks. The fire damaged only a waterline and a power line guy-wire, he added. Assuming that there are no other major delays, the mine will start production in summer 2022, in the middle of Idaho’s fire season.

Three days after my tour of the Jervois mine, I got a closer look at the damage wrought by the Blackbird Mine. On this trip, I was accompanied by the local site manager, George Lusher, and the reclamation manager, Mark TenBrink, both employees at the Anglo-Swiss multinational Glencore, one of the mining companies responsible for cleaning up the site. Lusher drove us in his Ford F-250. During the drive, I brought up electric vehicles. TenBrink, who lives in San Jose, said that he drives an electric Toyota RAV4 and loves it. Lusher was more skeptical. “I think electric cars are a great idea, especially for big cities,” he said. But they would “have to come a long way” before he would feel comfortable driving one. “I want to stay warm and I want to make it back,” he said.

One of our first stops was the Blackbird water-treatment plant, a windowless building made of corrugated metal and concrete and attached to what looked like an industrial-size aboveground pool. This is where contaminated water from the underground mine workings and several collection ponds is diverted before being released into Blackbird Creek. Standing on a catwalk above the pool, I watched as a revolving mechanical rake collected heavy metals that had coagulated into a sludge and sunk to the bottom. Within a day or two, one of the plant’s two full-time operators would load the sludge into a water tanker and haul it to one of three open-air basins farther up the site. There, it would be left to dry in the sun. TenBrink said that he has looked into sending the sludge to a smelter in Canada, where copper and cobalt could be extracted from it. But in the end, he concluded that doing so wasn’t economically feasible, so the sludge remains in the pits for now. I asked him when the water treatment would end. He didn’t have a date. “It’s really a very long way off,” he said.

Prospectors first discovered gold and copper around Blackbird Creek in the late 1800s, and in 1901, a man named John Belliel staked the first cobalt claim in the area, reportedly after he spotted a “cobalt bloom”—gray rock streaked with pink—near the creek. But it wasn’t until 1949 that full-scale mining operations began, spurred by federal subsidies designed to boost the nation’s mineral stockpile during the early years of the Cold War. Blackbird was the only primary producer of cobalt in the U.S., and for a decade it prospered. Cobalt, a company town that sprouted up a few miles east of the mine, was at one point home to 1,500 residents.

Blackbird’s boom years ended as quickly as they began. In 1959, the U.S. Office of Civil and Defense Mobilization announced that the national cobalt stockpile was “sufficiently large to meet all foreseeable mobilization requirements.” Having lost its largest buyer, the mine closed, and Cobalt, like countless mining communities before it, became a ghost town. By 1961, its population had dwindled to 20, and The New York Times predicted that the town was “likely to be given back to the forest, the deer and the hawk.”

Over the next three decades, a handful of companies tried to reopen the mine. For a few years in the 1960s, a Salt Lake City–based company extracted copper from its open pit. Subsequent owners spent years exploring the site’s remaining cobalt deposits, but the metal’s price remained too low for mining to be profitable. Finally, in 1982, the mine shut down for good. The following year, the state of Idaho sued the two companies that had come to share ownership of the mine, over the cobalt, copper, arsenic, and other heavy metals that had drained from the mine into Blackbird Creek and others.

The legal battle dragged on until 1995, when three past and present mine owners agreed to clean up the site and cover the cost of it themselves. Those companies, one of which was eventually acquired by Glencore, became known as the Blackbird Mine Site Group. Over the past 26 years, the group has restored creeks, sealed off mine portals, and constructed an intricate system of ponds and ditches designed to separate clean water from contaminated water. In the early 2000s, Chinook salmon returned to nearby Panther Creek.

Christopher Mebane, a self-described “dirty-water biologist” for the U.S. Geological Survey who has done fieldwork around Blackbird, told me that the site has come a long way since he first visited it, in the early 1990s. “It’s a glass that’s nine-tenths full,” he said. His main worry is that cleanup targets created specifically for Blackbird as part of the legal settlement allow for a concentration of cobalt that he believes is at least 10 times higher than is safe for many species of aquatic insects. Fortunately, the concentration of cobalt in the site’s discharge has mostly remained below the official limit—sometimes even below Mebane’s limit—for years, progress that Mebane attributes to the cleanup. Now, though, he worries that new mines will be allowed to adopt the same standard, as Jervois’s was, because state and federal agencies don’t have an alternative. “It’s just not protective,” Mebane said.

In the early 1950s, when production at Blackbird began to ramp up, its operating company built an earthen dam on the west fork of Blackbird Creek, not far from where John Belliel staked his initial claim. Over the next several decades, 2 million tons of tailings were dumped behind the dam. During my visit to the site, we stopped on top of it to see the tailings impoundment, a 20-acre soil-covered pit. I asked where the creek was. “You’re looking at it,” Lusher said. He pointed to a narrow concrete channel that cut across the impoundment and led to a spillway on the side of the dam. Were the dam to fail, there would be nothing to stop the tailings from tumbling into the main branch of Blackbird Creek, potentially reaching the Salmon River.

The channel was designed to withstand a 500-year flood, Lusher told me as we walked alongside it. But 500-year floods are exactly the kind of extreme-weather events that climate change could cause to occur more frequently. And while federal regulators have determined that the dam is structurally sound, it’s not impermeable even under normal conditions. Water sometimes seeps into the tailings impoundment, where it collects iron sulfide, and then drains into Blackbird Creek. The water isn’t polluted enough to require action under the current regulations, but its effects on the creek are impossible to miss. “Instead of blue rocks, you now have orange rocks,” TenBrink said. I didn’t ask how long until the rocks would return to their natural color. The answer seemed obvious.

The first thing Bret Riggan does when he gets home from work every day is crack open a Keystone Light. A gruff man with a thick mustache and even thicker drawl, Riggan lives with his dog, a young mutt named Richard, in a Silver Streak trailer parked on the Cobalt town site.

Riggan has worked as an operator at the Blackbird water-treatment plant since 1996. Unlike Lengerich, he hates the long drive to and from Salmon, which is why he decided to live out here. On the afternoon I met him, he was nailing a no trespassing sign to a fence post next to the gated entrance of the town site. He invited me to his trailer and offered me a beer. “I’m the mayor, the sheriff,” he told me as we drank on his deck. “I’m everything.” He is Cobalt’s only resident, and he likes it that way.

Despite widespread expectation that Cobalt would be abandoned after the federal government stopped subsidizing Blackbird in the late 1950s, the town survived for several more decades. Riggan himself lived there in the late 1970s and early 1980s, when he was in his early 20s and worked for a company that was exploring new ore deposits at the mine. At the time, Riggan told me, more than 100 other mine workers lived in Cobalt. Many, including him, were single men who crammed into three bunkhouses at the edge of town. The others lived in small, single-story houses with their families. The town had a recreation center with a bowling alley and a basketball court, and a mile or so outside of town was a popular bar called the Panther Creek Inn. “I spent a lot of time up there,” Riggan said. “Shed a lot of blood there—mine.” He didn’t go into details.

Today, only two houses remain in Cobalt, not including Riggan’s trailer. The rest have either been demolished or hauled away. Some ended up in Salmon, where they became homes to new families. Riggan helped burn down many of the others in the late 1990s. About a decade ago, he helped tear down the Panther Creek Inn, which had become a watering hole for hunters after the miners left. “That hurt me,” he said. Aside from the two houses, one of which has all but caved in on itself, the only other original structure that still exists in Cobalt is a dilapidated tank once used to store drinking water. After we finished our beers, Riggan took me to see it. Perched on a forested hill above the town site, its rusted walls were graffitied with the names of former residents. Riggan read out the names he recognized while reminiscing about skinny-dipping in the tank. “It ain’t much,” he said. “But it’s about all that’s left.”

It’s tempting to see Blackbird and Cobalt as cautionary tales—to conclude that mines will always create environmental disasters and that mining booms are always followed by devastating busts. And yet during the two weeks I spent in and around Salmon, many people I met expressed cautious optimism about the return of cobalt mining. Tammy Stringham, the executive director of the Lemhi County Economic Development Association, talked excitedly about how the industry could provide a boost to the local economy. She had heard that the Jervois mine alone would create as many as 150 jobs, though she was wary of getting her hopes up. It was hard to blame her. The Jervois mine had originally been scheduled to open in 2011 under a different owner, but volatility in the global cobalt market delayed construction for years.

Leo Marshall is the mayor of Salmon and, as it happens, a former resident of Cobalt. He lived there with his father, who worked at Blackbird, and his stepmother, for most of the 1950s. Having moved to Salmon in 1981and served as mayor since 2010, Marshall has experienced the cobalt boom-and-bust cycle firsthand. He hopes this time will be different, and he has good reason to think it will be. According to data from S&P Global Market Intelligence, cobalt prices were nearly 63 percent higher last year than they were in 2020, and electric vehicles are expected to account for nearly 70 percent of cobalt demand growth through 2025. On October 25, in a sign of the electric-vehicle market’s trajectory, Tesla’s market capitalization rose above $1 trillion for the first time.

One afternoon in Salmon, I visited a car dealership called Quality Motors, just down the road from the Jervois office. Parked out front were six F-150s and a Dodge Ram. When I asked the owner, Dave Hull, about electric vehicles, he told me that he didn’t expect to start selling them anytime soon. This didn’t surprise me. Many locals I met shared George Lusher’s doubts about their reliability, while others were simply resistant to change. And as far as I could tell, the only charging station in town was located on the side of my hotel, the Stagecoach Inn. Still, Hull didn’t doubt that electric vehicles would become commonplace in Salmon. “It’s just a matter of time,” he said. “We’re at least 10 years away, but it’s coming.” When we finished talking, I got back in my rental car, a Ford Fusion hybrid, and drove away.